Project Description

PTFE, HDPE, PC, POM, PP, Polyamide, PU, PVC

Type: Virgin, Carbon-filled, Bronze-filled, Glass-filled, Etched

Colour: White, Black, Brown, Red, Purple, Green

Available Shapes: Sheet, Rod, Hollow, Tubing, Strip

Common applications:

- High temperature seals

- Insulators

- Bearings

| Shape | Thickness / Diameters | Temperature Range |

|---|---|---|

| Molded sheets | 2.0 mm – 110 mm | -73°C to 204°C |

| Skived sheets | 0.2 mm – 6.0 mm | |

| Bars | 6 mm – 150 mm |

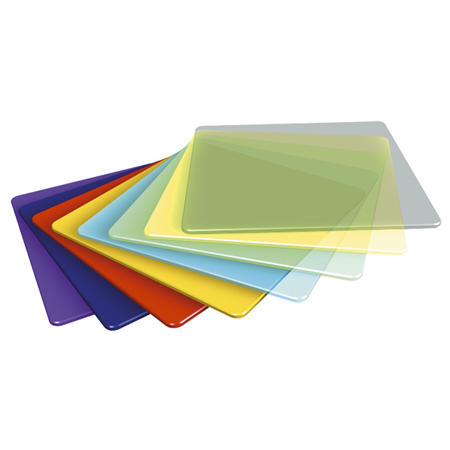

Type: 300, 500, 1000, UHMW

Colour: Natural, Green, Black

Available Shapes: Sheet, Rod, Tube

Key Features:

• Excellent chemical resistance

• Good fatigue & wear resistance

• Resists organic solvents, degreasing agents & electrolytic attack

• USDA & FDA certified for food processing

• Great cutting board materials

• Weatherproof

Common applications:

• Chemical drums

• Toys

• Households and kitchenwares

• Cable insulations

• Food wrapping materials

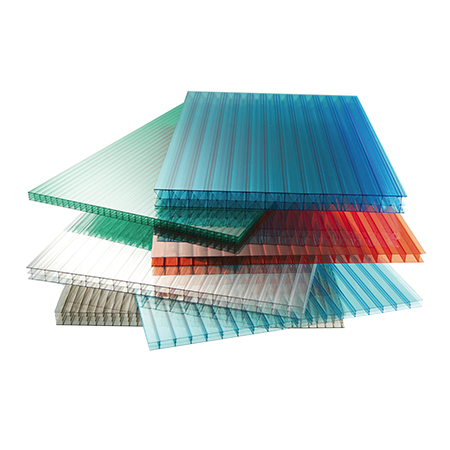

Colour: Clear, Green, Blue, Light blue, Brown, Opal, Red, Yellow

Shape: Sheet

Key Features:

• Thickness: 4mm – 6mm

• 100% virgin bayer/lexan material

• UV Protection (one side or two sides)

• Light weight

• Very high impact strength

• Good light transmission

• Good weather resistance

Common applications:

• Skylights

• Indoor partitions

• Furnitures

• Bathrooms

Colour: Natural , Black

Shape: Rod, Sheet

Key Features:

• High tensile strength

• Continuous rigidity and strength at temperatures up to 85°C

• Exceptional resistance to wear, impact, and creep in wet & dry environments

• Food-safe

• Easy to machine and fabricate

Common applications:

• Pistons and valves

• Pump components

• Gears, bearings and bushings

• Rollers

• Fittings

• Food products forming dies

Colour: Natural , Black

Shape: Rod, Sheet

Key Features:

• Lightweight

• Mechanically tough and rigid

• High purity

• Excellent chemical resistance

• No moisture absorption

Common applications:

• Pump and valve components

• Food processing plants

• Chemical processing

• Semiconductor manufacturing

Colour: Natural, Black, MD, Glass-filled, Oil-filled

Shape: Sheets & Bars

Key Features:

• High tensile strength

• High impact resistance

• Resists wear, abrasion and vibration

• Can withstand contact with chemicals, alkalis, dilute acids or oxidizing agents

• Very easy to fabricate

• Light weight

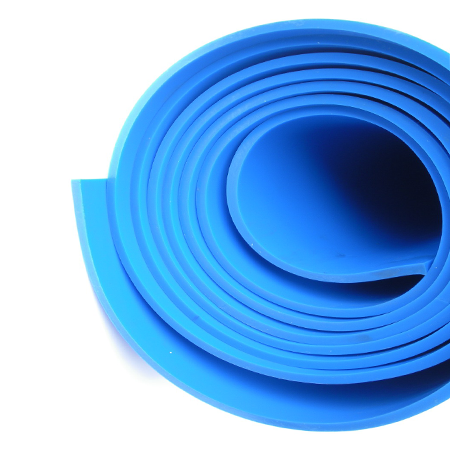

Colour: Yellow, Orange, Red, Black

Shape: Rod, Sheet, Angle, Square

Type: Polyurethane Elastomers (custom cast products) & Polyurethane Foams

Key Features:

• Abrasion resistance

• Toughness – tensile strength

• High load bearing ability

• High tear resistance

• Mechanical properties

• Resistance to water, oil & grease

• Electrical properties

• Cost effectiveness

Common applications:

• Gaskets

• Wheels

• Bearings

• Bumpers

• Seals

• Gears

Colour: Grey, Clear

Shape: Rod, Sheet, Angle, Square

Type: Rigid, Flexible

Key Features:

• Excellent chemical resistance

• Light-weight

• Low cost

• Maximum temperature of 68°C

• Easy to machine

Common applications:

• Flooring

• Medical products

• Window frames

• Insulations